Products

-

Encapsulated Incoloy 825 Chemical Injection Line

A general term for injection processes that use special chemical solutions to improve oil recovery, remove formation damage, clean blocked perforations or formation layers, reduce or inhibit corrosion, upgrade crude oil, or address crude oil flow-assurance issues. Injection can be administered continuously, in batches, in injection wells, or at times in production wells.

-

Encapsulated 316L Chemical Injection Line

A small-diameter conduit that is run alongside production tubulars to enable injection of inhibitors or similar treatments during production. Conditions such as high hydrogen sulfide [H2S] concentrations or severe scale deposition can be counteracted by injection of treatment chemicals and inhibitors during production.

-

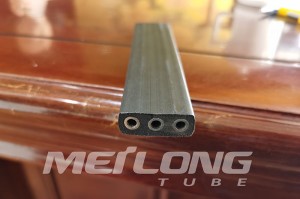

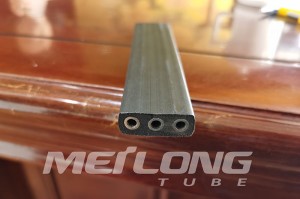

Encapsulated Hydraulic Control Line Tube

The encapsulation of downhole components such as Hydraulic Control Lines, Single Line Encapsulation, Dual-Line Encapsulation (FLATPACK), Triple-Line Encapsulation (FLATPACK) has become prevalent in downhole applications. The overlaying of plastic provides several benefits that help to ensure a successful completion.

-

Encapsulated Hydraulic Control Line

Control lines have undergone extensive development, including crush testing and high-pressure autoclave well simulation. Laboratory crush tests have demonstrated the increased loading under which encapsulated tubing can maintain functional integrity, particularly where wire-strand “bumper wires” are used.

-

Encapsulated Control Line Tubing

Options:

1. Wide range of single, dual, or triple flat-packs

2. Encapsulation materials to suit well conditions

3. Tubing in various grades of stainless steels and in nickel alloys

-

Encapsulated Control Line Tube

Applications:

1. Intelligent wells requiring the functionality and reservoir management benefits of remote flow-control devices because of the costs or risks of interventions or an inability to support the surface infrastructure required in a remote location

2. Land, platform, or subsea environments

-

Encapsulated Control Line

These lines can be custom configured for a variety of applications and downhole components.

The encapsulation of downhole components such as Hydraulic Control Lines, Single Line Encapsulation, Dual-Line Encapsulation (FLATPACK), Triple-Line Encapsulation (FLATPACK) has become prevalent in downhole applications.

-

Monel 400 Capillary Tubing Chemical Injection Line

A general term for injection processes that use special chemical solutions to improve oil recovery, remove formation damage, clean blocked perforations or formation layers, reduce or inhibit corrosion, upgrade crude oil, or address crude oil flow-assurance issues. Injection can be administered continuously, in batches, in injection wells, or at times in production wells.

To assure produced fluid flow and protect your production infrastructure from plugging and corrosion, you need reliable injection lines for your production chemical treatments. Chemical injection lines from Meilong Tube help enhance the efficiency of your production equipment and lines, both downhole and at surface.

-

Monel 400 Capillary Tube Chemical Injection Line

A small-diameter conduit that is run alongside production tubulars to enable injection of inhibitors or similar treatments during production. Conditions such as high hydrogen sulfide [H2S] concentrations or severe scale deposition can be counteracted by injection of treatment chemicals and inhibitors during production.

To assure produced fluid flow and protect your production infrastructure from plugging and corrosion, you need reliable injection lines for your production chemical treatments. Chemical injection lines from Meilong Tube help enhance the efficiency of your production equipment and lines, both downhole and at surface.

-

Monel 400 Chemical Injection Line Tubing

A general term for injection processes that use special chemical solutions to improve oil recovery, remove formation damage, clean blocked perforations or formation layers, reduce or inhibit corrosion, upgrade crude oil, or address crude oil flow-assurance issues. Injection can be administered continuously, in batches, in injection wells, or at times in production wells.

A small-diameter conduit that is run alongside production tubulars to enable injection of inhibitors or similar treatments during production. Conditions such as high hydrogen sulfide [H2S] concentrations or severe scale deposition can be counteracted by injection of treatment chemicals and inhibitors during production.

-

Monel 400 Chemical Injection Line Tube

Our tubing is characterized with integrity and quality to be specially used in subsea conditions in the industries of oil and gas extraction.

-

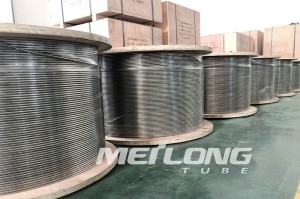

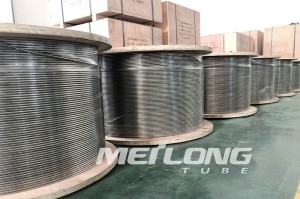

Monel 400 Chemical Injection Line

Unique manufacturing capabilities and processes allow Meilong Tube to produce the longest continuous chemical injection line tubing available in stainless steels and high nickel alloys. Our long length tubing coils are used extensively for chemical injection in subsea and onshore wells. The length without orbital welds which reduces the potential for defects and failures. Additionally, our coils have an extremely clean and smooth inside surface that is ideal for chemical injection systems. The coils offer short hydraulic response time, greater collapse strength, and elimination of methanol permeation.