Encapsulated Chemical Injection Line

-

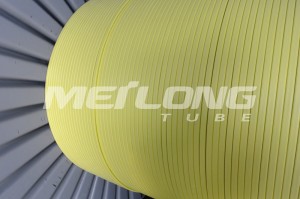

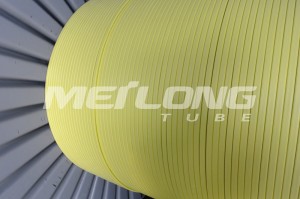

PVDF Encapsulated S32750 Chemical Injection Line Tube

Our long length tubing coils are used extensively for chemical injection in subsea and onshore wells. The length without orbital welds which reduces the potential for defects and failures.

-

PVDF Encapsulated N08825 Chemical Injection Line Tube

Unique manufacturing capabilities and processes allow Meilong Tube to produce the longest continuous chemical injection line tubing available in stainless steels and high nickel alloys.

-

PVDF Encapsulated 316L Chemical Injection Line Tubing

To assure produced fluid flow and protect your production infrastructure from plugging and corrosion, you need reliable injection lines for your production chemical treatments. Chemical injection lines from Meilong Tube help enhance the efficiency of your production equipment and lines, both downhole and at surface.

Our tubing is characterized with integrity and quality to be specially used in subsea conditions in the industries of oil and gas extraction, geothermal power generation.

-

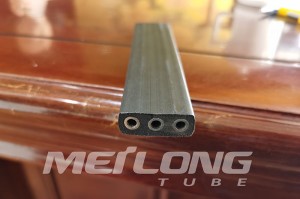

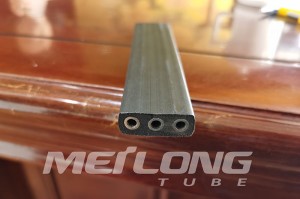

Rilsan Polyamide 11 Encapsulated S32750 Chemical Injection Line Tube

The engineering disciplines involved in flow assurance play an essential part in mapping the requirements that reduce or prevent loss of production due to pipeline or process equipment blockage. Coiled tubing from Meilong Tube is applied to umbilicals and chemical injection systems play an effective role in chemical storage and delivery at an optimizing flow assurance.

Our tubing is characterized with integrity and quality to be specially used in subsea conditions in the industries of oil and gas extraction.

-

Encapsulated N08825 Chemical Injection Line Tubing

One of the main challenges in the upstream processes of the oil and gas industry is to protect pipeline and process equipment against waxes, scaling and asphalthane deposits.

-

Rilsan PA 11 Encapsulated SAF 2507 Chemical Injection Line

Duplex 2507 is a super duplex stainless steel designed for applications which demand exceptional strength and corrosion resistance. Alloy 2507 has 25% chromium, 4% molybdenum, and 7% nickel. This high molybdenum, chromium and nitrogen content results in excellent resistance to chloride pitting and crevice corrosion attack and the duplex structure provides 2507 with exceptional resistance to chloride stress corrosion cracking.

-

Encapsulated Incoloy 825 Chemical Injection Line

A general term for injection processes that use special chemical solutions to improve oil recovery, remove formation damage, clean blocked perforations or formation layers, reduce or inhibit corrosion, upgrade crude oil, or address crude oil flow-assurance issues. Injection can be administered continuously, in batches, in injection wells, or at times in production wells.

-

Encapsulated 316L Chemical Injection Line

A small-diameter conduit that is run alongside production tubulars to enable injection of inhibitors or similar treatments during production. Conditions such as high hydrogen sulfide [H2S] concentrations or severe scale deposition can be counteracted by injection of treatment chemicals and inhibitors during production.