Manufacturing Companies for Monel 400 Chemical Injection Tube - Monel 400 Chemical Injection Line Tube – MEILONG

Manufacturing Companies for Monel 400 Chemical Injection Tube - Monel 400 Chemical Injection Line Tube – MEILONG Detail:

Product Introduction

A general term for injection processes that use special chemical solutions to improve oil recovery, remove formation damage, clean blocked perforations or formation layers, reduce or inhibit corrosion, upgrade crude oil, or address crude oil flow-assurance issues. Injection can be administered continuously, in batches, in injection wells, or at times in production wells.

A small-diameter conduit that is run alongside production tubulars to enable injection of inhibitors or similar treatments during production. Conditions such as high hydrogen sulfide [H2S] concentrations or severe scale deposition can be counteracted by injection of treatment chemicals and inhibitors during production.

To assure produced fluid flow and protect your production infrastructure from plugging and corrosion, you need reliable injection lines for your production chemical treatments. Chemical injection lines from Meilong Tube help enhance the efficiency of your production equipment and lines, both downhole and at surface.

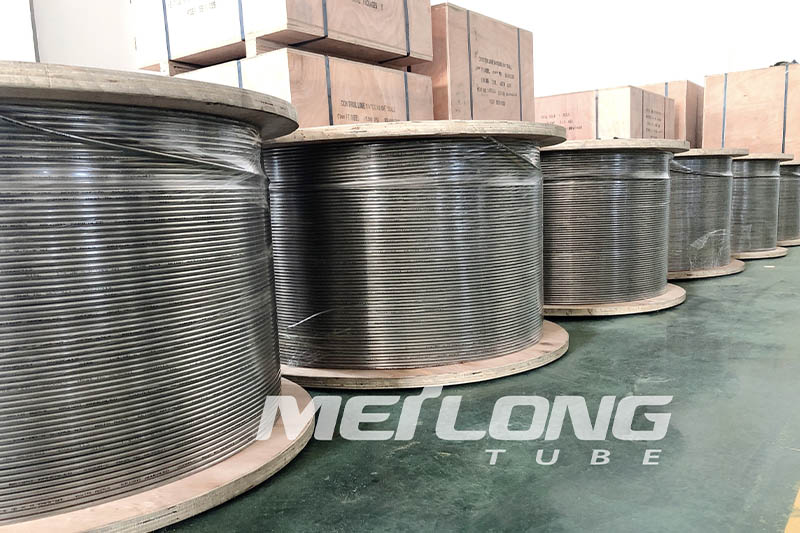

Product Display

Alloy Feature

Monel 400 is a nickel-copper alloy (about 67% Ni – 23% Cu) that is resistant to sea water and steam at high temperatures as well as to salt and caustic solutions. Alloy 400 is a solid solution alloy that can only be hardened by cold working. This nickel alloy exhibits characteristics like good corrosion resistance, good weldability and high strength. A low corrosion rate in rapidly flowing brackish or seawater combined with excellent resistance to stress-corrosion cracking in most freshwaters, and its resistance to a variety of corrosive conditions led to its wide use in marine applications and other non-oxidizing chloride solutions. This nickel alloy is particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated.

Dimensional Tolerance

| ASTM B730 / ASME SB730, Monel 400, UNS N04400 | ||

| ASTM B751 / ASME SB751 | ||

| Size OD | Tolerance OD | Tolerance WT |

| 1/8’’<OD<5/8’’ (3.18<OD<15.88 mm) | ±0.004’’ (±0.10 mm) | ±12.5% |

| 5/8’’≤OD≤1’’ (15.88≤OD≤25.4 mm) | ±0.0075’’ (±0.19 mm) | ±12.5% |

| Meilong Standard | ||

| Size OD | Tolerance OD | Tolerance WT |

| 1/8’’<OD<5/8’’ (3.18<OD<15.88 mm) | ±0.004’’ (±0.10 mm) | ±10% |

| 5/8’’≤OD≤1’’ (15.88≤OD≤25.4 mm) | ±0.004’’ (±0.10 mm) | ±8% |

Product detail pictures:

Related Product Guide:

Dependable good quality and very good credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality initial, shopper supreme" for Manufacturing Companies for Monel 400 Chemical Injection Tube - Monel 400 Chemical Injection Line Tube – MEILONG , The product will supply to all over the world, such as: Armenia, Finland, Peru, Based on products and solutions with high quality, competitive price, and our full range service, we have accumulated experienced strength and experience, and we've built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality items and passionate service. Let's open a new chapter of mutual benefit and double win.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.