Wholesale Nickel Alloy Control Line Tubing - Encapsulated 316L Hydraulic Control Line Flatpack – MEILONG

Wholesale Nickel Alloy Control Line Tubing - Encapsulated 316L Hydraulic Control Line Flatpack – MEILONG Detail:

Alloy Feature

SS316L is an austenitic chromium-nickel stainless steel with molybdenum and a low carbon content.

Corrosion Resistance

Organic acids at high concentrations and moderate temperatures

Inorganic acids, e.g. phosphoric and sulphuric acids, at moderate concentrations and temperatures. The steel can also be used in sulphuric acid of concentrations above 90% at low temperature.

Salt solutions, e.g. sulphates, sulphides and sulphites

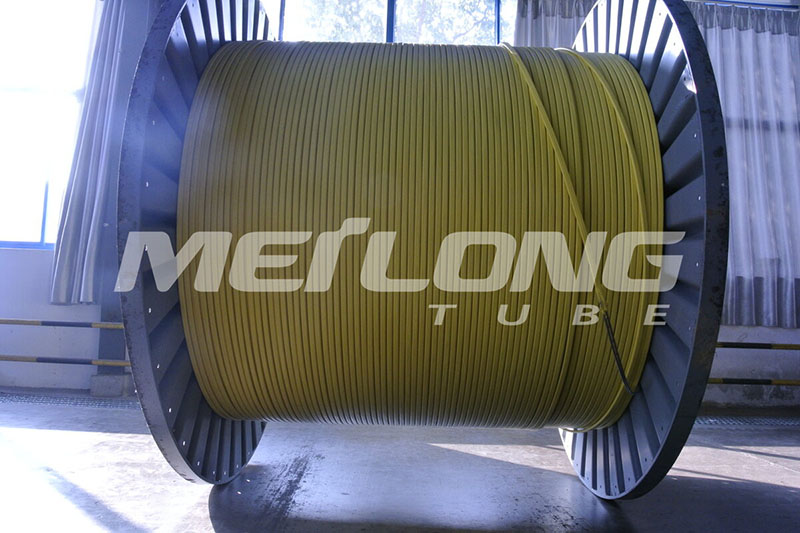

Product Display

Chemical Composition

|

Carbon |

Manganese |

Phosphorus |

Sulfur |

Silicon |

Nickel |

Chromium |

Molybdenum |

|

% |

% |

% |

% |

% |

% |

% |

% |

|

max. |

max. |

max. |

max. |

max. |

|

|

|

|

0.035 |

2.00 |

0.045 |

0.030 |

1.00 |

10.0-15.0 |

16.0-18.0 |

2.00-3.00 |

Norm Equivalence

|

Grade |

UNS No |

Euro norm |

Japanese |

|

|

No |

Name |

JIS |

||

| Alloy | ASTM/ASME | EN10216-5 | EN10216-5 | JIS G3463 |

| 316L | S31603 | 1.4404, 1.4435 | X2CrNiMo17-12-2 | SUS316LTB |

Application

For SSSV (sub-surface safety valve)

A safety valve is a valve that acts as the protector of your equipment. Safety valves can prevent damage to your pressure vessels and even prevent explosions at your facility when installed in pressure vessels.

A safety valve is a type of valve that automatically actuates when the pressure of the inlet side of the valve increases to a predetermined pressure, to open the valve disc and discharge the fluid. The safety valve system is designed to be a fail-safe so that a wellbore can be isolated in the event of any system failure or damage to the surface production-control facilities.

In most cases, it is mandatory to have a means of closure for all wells capable of natural flow to the surface. The installation of a subsurface safety valve (SSSV) will provide this emergency closure capability. Safety systems may be operated on a fail-safe principle from a control panel located on the surface.

Product detail pictures:

Related Product Guide:

Our mission is to become an innovative supplier of high-tech digital and communication devices by providing value added design, world-class manufacturing, and service capabilities for Wholesale Nickel Alloy Control Line Tubing - Encapsulated 316L Hydraulic Control Line Flatpack – MEILONG , The product will supply to all over the world, such as: Slovenia, Macedonia, Boston, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to provide our clients sincerely with qualified products, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.