Top Quality S32750 Chemical Injection Line Tubing - Incoloy 825 Capillary Tube Chemical Injection Line – MEILONG

Top Quality S32750 Chemical Injection Line Tubing - Incoloy 825 Capillary Tube Chemical Injection Line – MEILONG Detail:

Testing Abilities

| Chemical | Flare | Metallurgical |

| Corrosion | Flatten | Positive material identification (PMI) |

| Dimensional | Grain size | Surface roughness |

| Eddy current | Hardness | Tensile |

| Elongation | Hydrostatic | Yield |

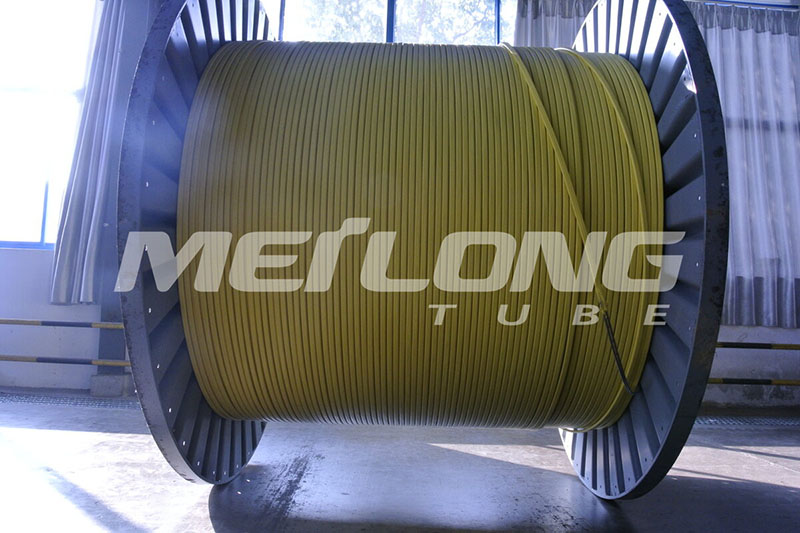

Product Display

Technical Datasheet

|

Alloy |

O.D. |

W.T. |

Yield Strength |

Tensile Strength |

Elongation |

Hardness |

Working Pressure |

Burst Pressure |

Collapse Pressure |

|

inch |

inch |

Mpa |

Mpa |

% |

HV |

psi |

psi |

psi |

|

|

|

|

min. |

min. |

min. |

max. |

min. |

min. |

min. |

|

|

Incoloy 825 |

0.375 |

0.035 |

241 |

586 |

30 |

209 |

4,906 |

19,082 |

6,510 |

|

Incoloy 825 |

0.375 |

0.049 |

241 |

586 |

30 |

209 |

7,040 |

27,393 |

8,711 |

|

Incoloy 825 |

0.375 |

0.065 |

241 |

586 |

30 |

209 |

9,653 |

37,556 |

11,024 |

|

Incoloy 825 |

0.375 |

0.083 |

241 |

586 |

30 |

209 |

12,549 |

48,818 |

13,347 |

Dimensional Tolerance

| ASTM B704 / ASME SB704, Incoloy 825, UNS N08825 | ||

| ASTM B751 / ASME SB751 | ||

| Size OD | Tolerance OD | Tolerance WT |

| 1/8’’≤OD<5/8’’ (3.18≤OD<15.88 mm) | ±0.004’’ (±0.10 mm) | ±12.5% |

| 5/8≤OD≤1’’ (15.88≤OD≤25.4 mm) | ±0.0075’’ (±0.19 mm) | ±12.5% |

| Meilong Standard | ||

| Size OD | Tolerance OD | Tolerance WT |

| 1/8’’≤OD<5/8’’ (3.18≤OD<15.88 mm) | ±0.004’’ (±0.10 mm) | ±10% |

| 5/8≤OD≤1’’ (15.88≤OD≤25.4 mm) | ±0.004’’ (±0.10 mm) | ±8% |

Chemical Composition

|

Nickel |

Chromium |

Iron |

Molybdenum |

Carbon |

Manganese |

Silicon |

Sulfur |

Aluminum |

Titanium |

Copper |

|

% |

% |

% |

% |

% |

% |

% |

% |

% |

% |

% |

|

|

|

min. |

|

max. |

max. |

max. |

max. |

max. |

|

|

|

38.0-46.0 |

19.5-23.5 |

22.0 |

2.5-3.5 |

0.05 |

1.0 |

0.5 |

0.03 |

0.2 |

0.6-1.2 |

1.5-3.0 |

| Norm Equivalence | |||

|

Grade |

UNS No |

Euro norm |

|

|

No |

Name |

||

| Alloy | ASTM/ASME | EN10216-5 | EN10216-5 |

| 825 | N08825 | 2.4858 | NiCr21Mo |

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer you excellent services to just about every client, but also are ready to receive any suggestion offered by our buyers for Top Quality S32750 Chemical Injection Line Tubing - Incoloy 825 Capillary Tube Chemical Injection Line – MEILONG , The product will supply to all over the world, such as: Qatar, Netherlands, Liberia, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!

Write your message here and send it to us