OEM Supply 316L Chemical Injection Line Tubing - Super Duplex 2507 Chemical Injection Line Tube – MEILONG

OEM Supply 316L Chemical Injection Line Tubing - Super Duplex 2507 Chemical Injection Line Tube – MEILONG Detail:

Product introduction

One of the main challenges in the upstream processes of the oil and gas industry is to protect pipeline and process equipment against waxes, scaling and asphalthane deposits. The engineering disciplines involved in flow assurance play an essential part in mapping the requirements that reduce or prevent loss of production due to pipeline or process equipment blockage. Coiled tubing from Meilong Tube is applied to umbilicals and chemical injection systems play an effective role in chemical storage and delivery at an optimizing flow assurance.

Our tubing is characterized with integrity and quality to be specially used in subsea conditions in the industries of oil and gas extraction.

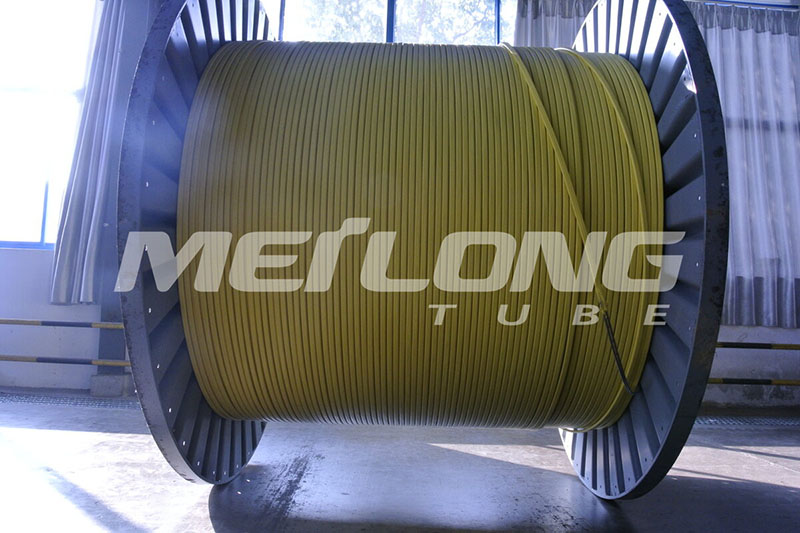

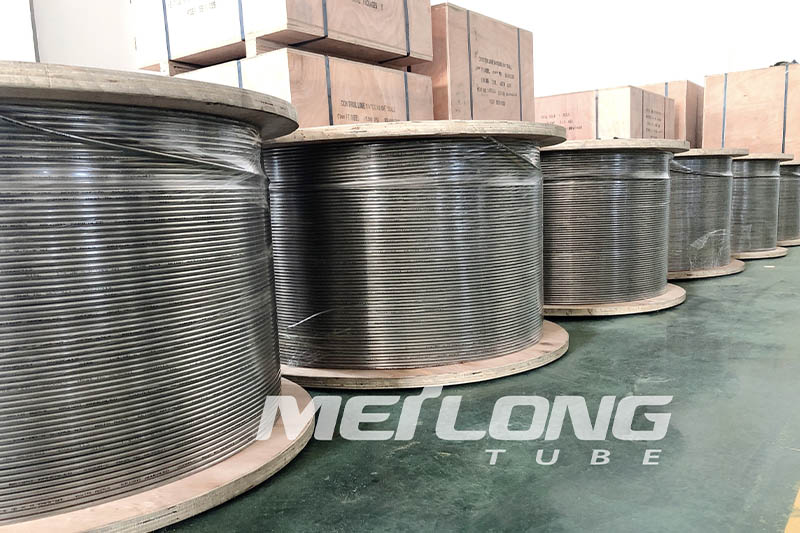

Product Display

Alloy Feature

Corrosion Resistance

2507 Duplex is highly resistant to uniform corrosion by organic ac Super Duplex 2507 Plateids such as formic and acetic acid. It is also highly resistant to inorganic acids, especially if they contain chlorides. Alloy 2507 is highly resistant to carbide-related intergranular corrosion. Due to the ferritic portion of the duplex structure of the alloy it is very resistant to stress corrosion cracking in warm chloride containing environments. Through additions of chromium, molybdenum and nitrogen localized corrosion such as pitting and crevice attack are improved. Alloy 2507 has excellent localized pitting resistance.

Characteristics

High resistance to chloride stress corrosion cracking.

High Strength.

Superior resistance to chloride pitting and crevice corrosion.

Good general corrosion resistance.

Suggested for applications up to 600° F.

Low rate of thermal expansion.

Combination of properties given by austenitic and ferritic structure.

Good weldability and workability.

Chemical Composition

|

Carbon |

Manganese |

Phosphorus |

Sulfur |

Silicon |

Nickel |

Chromium |

Molybdenum |

Nitrogen |

Copper |

|

% |

% |

% |

% |

% |

% |

% |

% |

% |

% |

|

max. |

max. |

max. |

max. |

max. |

max. |

||||

|

0.03 |

1.20 |

0.035 |

0.020 |

0.80 |

6.0-8.0 |

24.0-26.0 |

3.0-5.0 |

0.24-0.32 |

0.5 |

|

Norm Equivalence |

|||

|

Grade |

UNS No |

Euro norm |

|

|

No |

Name |

||

| Alloy | ASTM/ASME | EN10216-5 | EN10216-5 |

| 2507 | S32750 | 1.4410 | X2CrNiMoN25-7-4 |

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority of the crucial certifications of its market for OEM Supply 316L Chemical Injection Line Tubing - Super Duplex 2507 Chemical Injection Line Tube – MEILONG , The product will supply to all over the world, such as: UK, Jordan, Gabon, We are proud to supply our products to every costumer all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.