OEM manufacturer Alloy 625 Chemical Injection Tubing - Super Duplex 2507 Chemical Injection Line Tubing – MEILONG

OEM manufacturer Alloy 625 Chemical Injection Tubing - Super Duplex 2507 Chemical Injection Line Tubing – MEILONG Detail:

Product introduction

One of the main challenges in the upstream processes of the oil and gas industry is to protect pipeline and process equipment against waxes, scaling and asphalthane deposits. The engineering disciplines involved in flow assurance play an essential part in mapping the requirements that reduce or prevent loss of production due to pipeline or process equipment blockage. Coiled tubing from Meilong Tube is applied to umbilicals and chemical injection systems play an effective role in chemical storage and delivery at an optimizing flow assurance.

Our tubing is characterized with integrity and quality to be specially used in subsea conditions in the industries of oil and gas extraction.

A general term for injection processes that use special chemical solutions to improve oil recovery, remove formation damage, clean blocked perforations or formation layers, reduce or inhibit corrosion, upgrade crude oil, or address crude oil flow-assurance issues. Injection can be administered continuously, in batches, in injection wells, or at times in production wells.

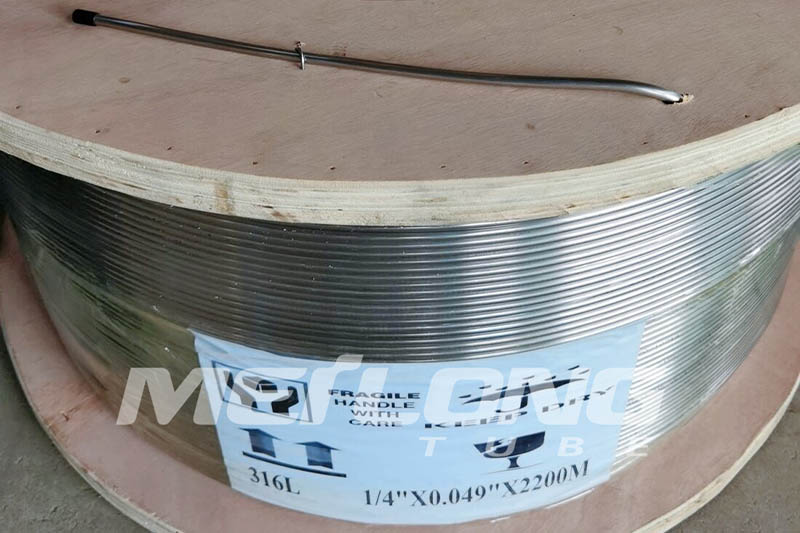

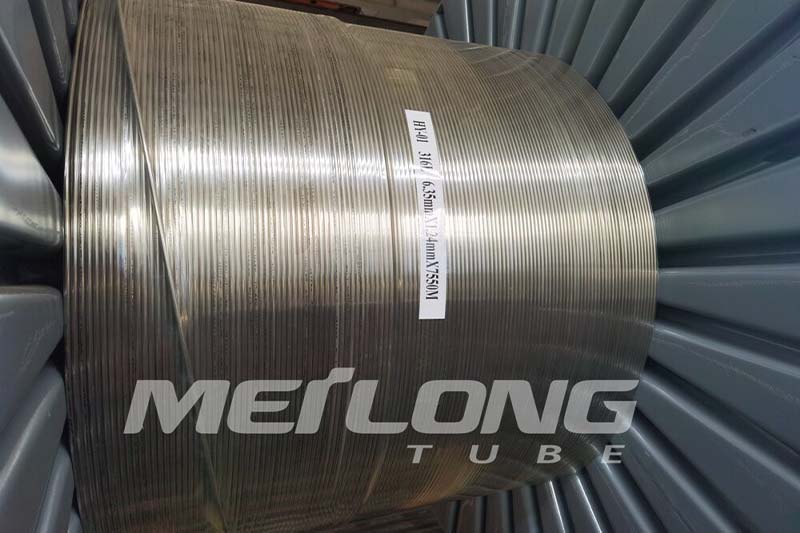

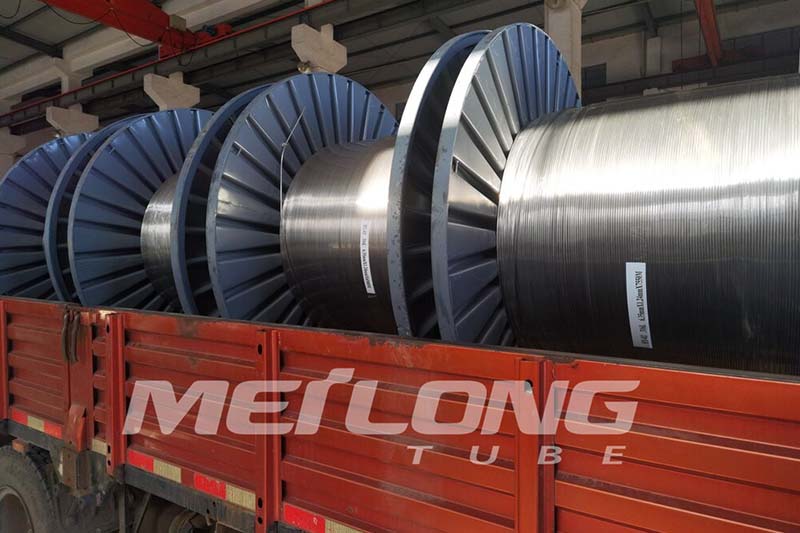

Product Display

Alloy Feature

Characteristics

High resistance to chloride stress corrosion cracking.

High Strength.

Superior resistance to chloride pitting and crevice corrosion.

Good general corrosion resistance.

Suggested for applications up to 600° F.

Low rate of thermal expansion.

Combination of properties given by austenitic and ferritic structure.

Good weldability and workability.

Application

Desalination Equipment.

Chemical process pressure vessels, piping and heat exchangers.

Marine Applications.

Flue Gas Scrubbing Equipment.

Pulp & Paper Mill Equipment.

Offshore Oil production/technology.

Oil and gas industry equipment.

Dimensional Tolerance

| ASTM A789 / ASME SA789, Super Duplex 2507, UNS S32750 | ||

| Size OD | Tolerance OD | Tolerance WT |

| <1/2’’ (<12.7 mm) | ±0.005’’ (±0.13 mm) | ±15% |

| 1/2’’ ≤OD≤1’’ (12.7≤OD≤25.4 mm) | ±0.005’’ (±0.13 mm) | ±10% |

| Meilong Standard | ||

| Size OD | Tolerance OD | Tolerance WT |

| <1/2’’ (<12.7 mm) | ±0.004’’ (±0.10 mm) | ±10% |

| 1/2’’ ≤OD≤1’’ (12.7≤OD≤25.4 mm) | ±0.004’’ (±0.10 mm) | ±8% |

Product detail pictures:

Related Product Guide:

We're committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for OEM manufacturer Alloy 625 Chemical Injection Tubing - Super Duplex 2507 Chemical Injection Line Tubing – MEILONG , The product will supply to all over the world, such as: Seattle, Gabon, French, We accomplish this by exporting our wigs directly from our own factory to you. The goal of our company is to get customers who enjoy coming back to their business. We sincerely hope to cooperate with you in the near future. If there's any opportunity, welcome to visit our factory!!!

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!