OEM Manufacturer Alloy 625 Chemical Injection Line - Encapsulated Control Line Tube – MEILONG

OEM Manufacturer Alloy 625 Chemical Injection Line - Encapsulated Control Line Tube – MEILONG Detail:

Product Introduction

Features, Advantages and Benefits

- Control lines are delivered in orbital-weld-free lengths up to 40,000 ft (12,192 m) to maximize reliability.

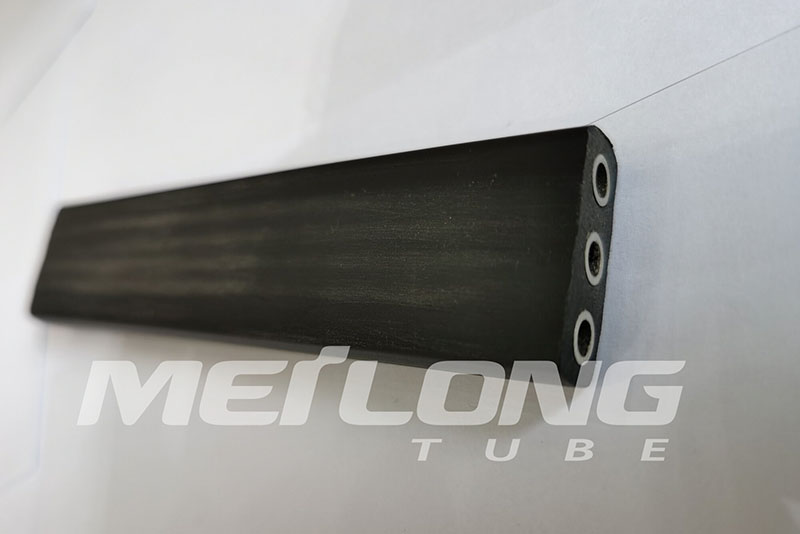

- A wide range of single, dual, or triple flat-packs is available. Flat-packs can be combined with downhole electrical cables and/or bumper wires for easier operation and handling during deployment.

- Welded-and-plug-drawn production method ensures a smooth, round tube to allow long-term metal sealing of terminations.

- Encapsulation materials are selected to suit well conditions, ensuring longevity and reliability.

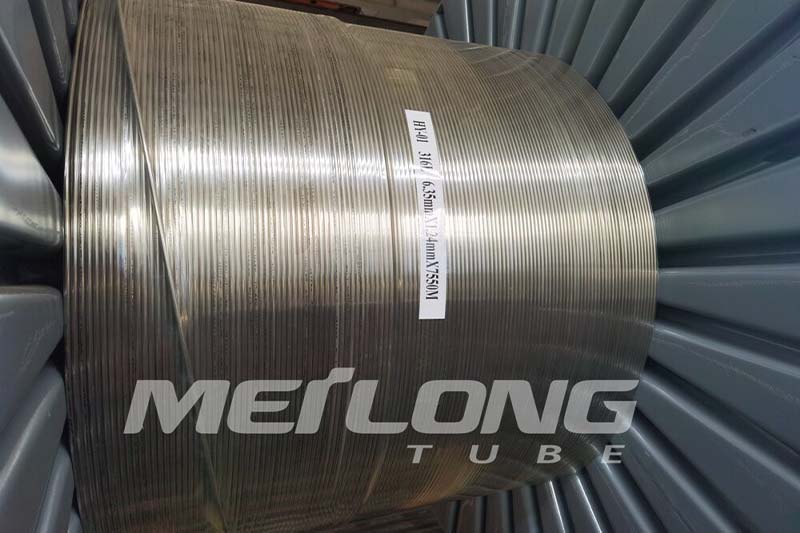

Product Display

Alloy Feature

Corrosion Resistance

Organic acids at high concentrations and moderate temperatures.

Inorganic acids, e.g. phosphoric and sulphuric acids, at moderate concentrations and temperatures. The steel can also be used in sulphuric acid of concentrations above 90% at low temperature.

Salt solutions, e.g. sulphates, sulphides and sulphites.

Caustic Environments

Austenitic steels are susceptible to stress corrosion cracking. This may occur at temperatures above about 60°C (140°F) if the steel is subjected to tensile stresses and at the same time comes into contact with certain solutions, particularly those containing chlorides. Such service conditions should therefore be avoided. Conditions when plants are shut down must also be considered, as the condensates which are then formed can develop conditions that lead to both stress corrosion cracking and pitting.

SS316L has a low carbon content and therefore better resistance to intergranular corrosion than steels of type SS316.

Dimensional Tolerance

| ASTM A269 / ASME SA269, 316L, UNS S31603 | ||

| Size OD | Tolerance OD | Tolerance WT |

| ≤1/2’’ (≤12.7 mm) | ±0.005’’ (±0.13 mm) | ±15% |

| 1/2’’<OD≤1’’ (12.7<OD≤25.4 mm) | ±0.005’’ (±0.13 mm) | ±10% |

| Meilong Standard | ||

| Size OD | Tolerance OD | Tolerance WT |

| ≤1/2’’ (≤12.7 mm) | ±0.004’’ (±0.10 mm) | ±10% |

| 1/2’’<OD≤1’’ (12.7<OD≤25.4 mm) | ±0.004’’ (±0.10 mm) | ±8% |

Product detail pictures:

Related Product Guide:

We not only will try our greatest to present fantastic expert services to each purchaser, but also are ready to receive any suggestion offered by our prospects for OEM Manufacturer Alloy 625 Chemical Injection Line - Encapsulated Control Line Tube – MEILONG , The product will supply to all over the world, such as: Panama, Swiss, United Arab Emirates, Only for accomplishing the good-quality product to meet customer's demand, all of our products have been strictly inspected before shipment. We always think about the question on the side of the customers, because you win, we win!

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.