OEM Manufacturer 316L Chemical Injection Tube - Incoloy 825 Chemical Injection Line Tubing – MEILONG

OEM Manufacturer 316L Chemical Injection Tube - Incoloy 825 Chemical Injection Line Tubing – MEILONG Detail:

Typical Tubing Size

Outside diameter of control lines is mainly 3/8’’ (9.53mm).

Wall thicknesses: 0.035’’ (0.89mm), 0.049’’ (1.24mm), 0.065’’ (1.65mm), 0.083’’ (2.11mm)

Injection line tubing is available in lengths from 400 feet (122 meters) to 32,808 feet (10,000 meters). No orbitally butt welds.

Other specifications (1/8’’ to 3/4’’) are available on request.

|

Imperial size |

Metric size |

||

|

OD inch |

WT inch |

OD mm |

WT mm |

|

1/8 (0.125) |

0.028 |

3.18 |

0.71 |

|

0.035 |

3.18 |

0.89 |

|

|

3/16 (0.188) |

0.028 |

4.76 |

0.71 |

|

0.035 |

4.76 |

0.89 |

|

|

0.049 |

4.76 |

1.24 |

|

|

1/4 (0.250) |

0.035 |

6.35 |

0.89 |

|

0.049 |

6.35 |

1.24 |

|

|

0.065 |

6.35 |

1.65 |

|

|

0.083 |

6.35 |

2.11 |

|

|

3/8 (0.375) |

0.035 |

9.53 |

0.89 |

|

0.049 |

9.53 |

1.24 |

|

|

0.065 |

9.53 |

1.65 |

|

|

0.083 |

9.53 |

2.11 |

|

|

1/2 (0.500) |

0.035 |

12.7 |

0.89 |

|

0.049 |

12.7 |

1.24 |

|

|

0.065 |

12.7 |

1.65 |

|

|

0.083 |

12.7 |

2.11 |

|

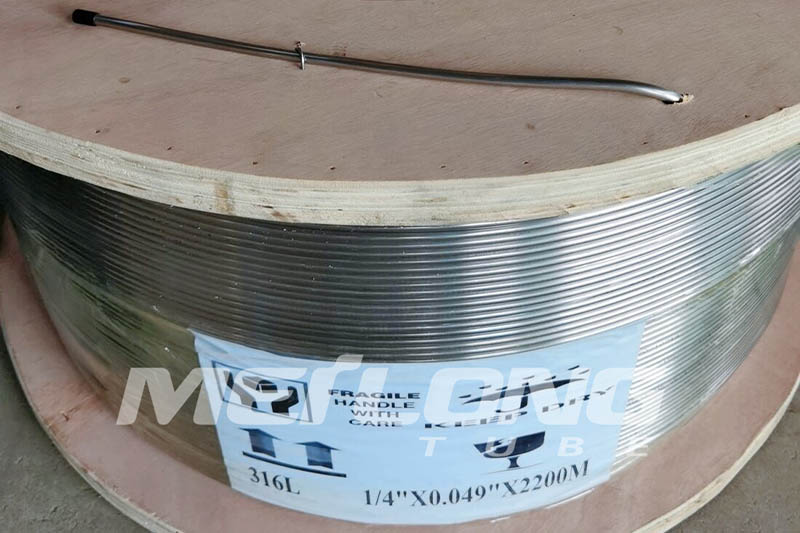

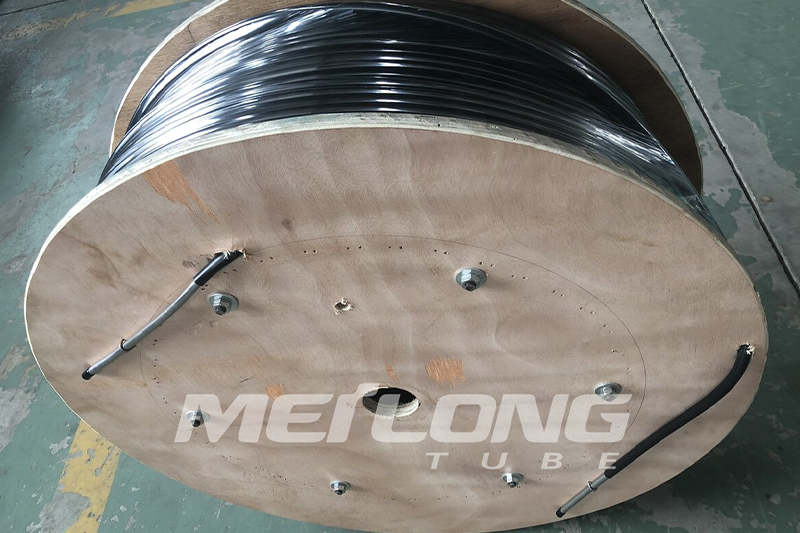

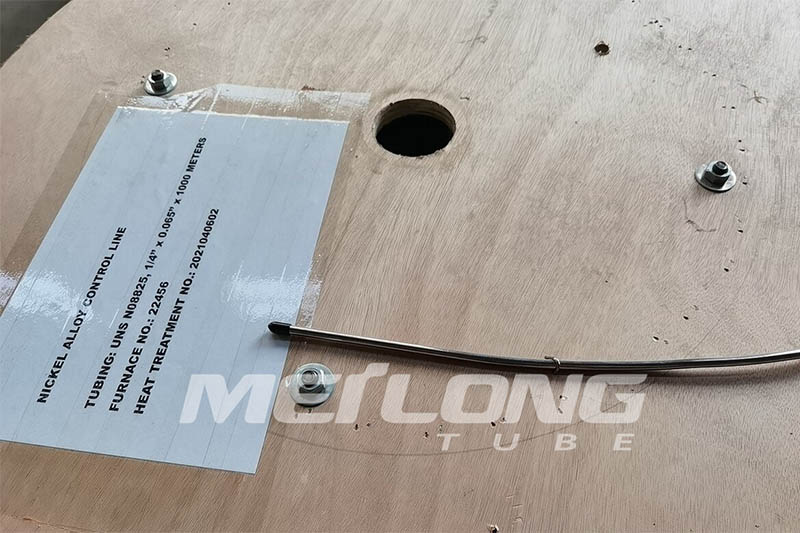

Product Display

Alloy Feature

Incoloy alloy 825 is a nickel-iron-chromium alloy with additions of molybdenum and copper. This nickel steel alloy’s chemical composition is designed to provide exceptional resistance to many corrosive environments. It is similar to alloy 800 but has improved resistance to aqueous corrosion. It has excellent resistance to both reducing and oxidizing acids, to stress-corrosion cracking, and to localized attack such as pitting and crevice corrosion. Alloy 825 is especially resistant to sulfuric and phosphoric acids. This nickel steel alloy is used for chemical processing, pollution-control equipment, oil and gas well piping, nuclear fuel reprocessing, acid production, and pickling equipment.

Application

Chemical Processing.

Pollution-control.

Oil and gas well piping.

Nuclear fuel reprocessing.

Components in pickling equipment like heating coils, tanks, baskets and chains.

Acid production.

Technical Datasheet

|

Alloy |

O.D. |

W.T. |

Yield Strength |

Tensile Strength |

Elongation |

Hardness |

Working Pressure |

Burst Pressure |

Collapse Pressure |

|

inch |

inch |

Mpa |

Mpa |

% |

HV |

psi |

psi |

psi |

|

|

|

|

min. |

min. |

min. |

max. |

min. |

min. |

min. |

|

|

Incoloy 825 |

0.375 |

0.035 |

241 |

586 |

30 |

209 |

4,906 |

19,082 |

6,510 |

|

Incoloy 825 |

0.375 |

0.049 |

241 |

586 |

30 |

209 |

7,040 |

27,393 |

8,711 |

|

Incoloy 825 |

0.375 |

0.065 |

241 |

586 |

30 |

209 |

9,653 |

37,556 |

11,024 |

|

Incoloy 825 |

0.375 |

0.083 |

241 |

586 |

30 |

209 |

12,549 |

48,818 |

13,347 |

Product detail pictures:

Related Product Guide:

Our mission will be to become an innovative supplier of high-tech digital and communication devices by furnishing benefit added structure, world-class manufacturing, and service capabilities for OEM Manufacturer 316L Chemical Injection Tube - Incoloy 825 Chemical Injection Line Tubing – MEILONG , The product will supply to all over the world, such as: Guatemala, Swaziland, Detroit, By integrating manufacturing with foreign trade sectors, we can offer total customer solutions by guaranteeing the delivery of right items to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified product portfolios and the control of the industry trend as well as our mature before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.