Factory Promotional Alloy 825 Capillary String - FEP Encapsulated 316L Chemical Injection Line – MEILONG

Factory Promotional Alloy 825 Capillary String - FEP Encapsulated 316L Chemical Injection Line – MEILONG Detail:

Typical Tubing Size

Outside diameter of control lines is mainly 3/8’’ (9.53mm).

Wall thicknesses: 0.035’’ (0.89mm), 0.049’’ (1.24mm), 0.065’’ (1.65mm), 0.083’’ (2.11mm)

Injection line tubing is available in lengths from 400 feet (122 meters) to 32,808 feet (10,000 meters). No orbitally butt welds.

Other specifications (1/8’’ to 3/4’’) are available on request.

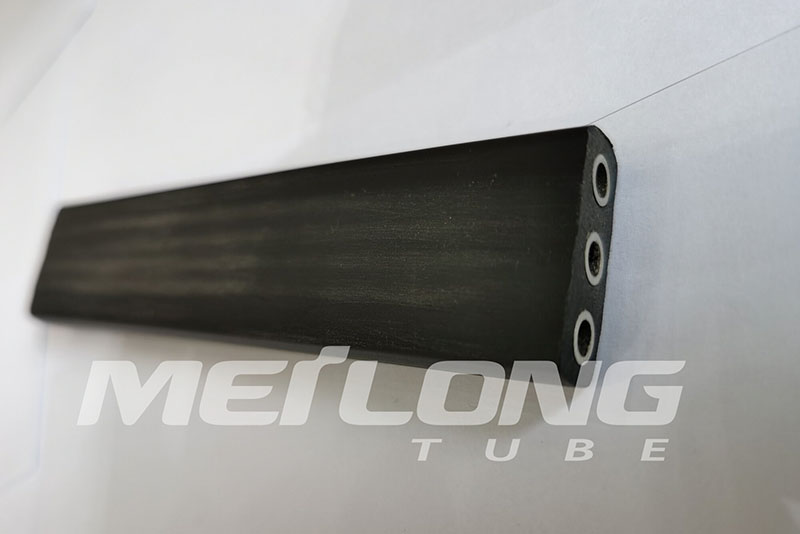

Product Display

Alloy Feature

Corrosion Resistance

Organic acids at high concentrations and moderate temperatures.

Inorganic acids, e.g. phosphoric and sulphuric acids, at moderate concentrations and temperatures. The steel can also be used in sulphuric acid of concentrations above 90% at low temperature.

Salt solutions, e.g. sulphates, sulphides and sulphites.

Caustic Environments

Austenitic steels are susceptible to stress corrosion cracking. This may occur at temperatures above about 60°C (140°F) if the steel is subjected to tensile stresses and at the same time comes into contact with certain solutions, particularly those containing chlorides. Such service conditions should therefore be avoided. Conditions when plants are shut down must also be considered, as the condensates which are then formed can develop conditions that lead to both stress corrosion cracking and pitting.

SS316L has a low carbon content and therefore better resistance to intergranular corrosion than steels of type SS316.

Technical Datasheet

|

Alloy |

O.D. |

W.T. |

Yield Strength |

Tensile Strength |

Elongation |

Hardness |

Working Pressure |

Burst Pressure |

Collapse Pressure |

|

inch |

inch |

Mpa |

Mpa |

% |

HV |

psi |

psi |

psi |

|

|

|

|

min. |

min. |

min. |

max. |

min. |

min. |

min. |

|

|

SS316L |

0.375 |

0.035 |

172 |

483 |

35 |

190 |

3,818 |

17,161 |

5,082 |

|

SS316L |

0.375 |

0.049 |

172 |

483 |

35 |

190 |

5,483 |

24,628 |

6,787 |

|

SS316L |

0.375 |

0.065 |

172 |

483 |

35 |

190 |

7,517 |

33,764 |

8,580 |

|

SS316L |

0.375 |

0.083 |

172 |

483 |

35 |

190 |

9,749 |

43,777 |

10,357 |

Product detail pictures:

Related Product Guide:

Our company insists all along the quality policy of "product quality is base of enterprise survival; customer satisfaction is the staring point and ending of an enterprise; persistent improvement is eternal pursuit of staff" and the consistent purpose of "reputation first, customer first" for Factory Promotional Alloy 825 Capillary String - FEP Encapsulated 316L Chemical Injection Line – MEILONG , The product will supply to all over the world, such as: Swedish, Eindhoven, Argentina, To create more creative products, maintain high-quality products and update not only our products but ourselves so as to keep us ahead of the world, and the last but most vital one: to make every client satisfied with everything we offer and to grow stronger together. To be the real winner, starts here!

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.