factory customized Alloy 825 Chemical Injection Line Tube - Chemical Injection Line – MEILONG

factory customized Alloy 825 Chemical Injection Line Tube - Chemical Injection Line – MEILONG Detail:

Product introduction

A general term for injection processes that use special chemical solutions to improve oil recovery, remove formation damage, clean blocked perforations or formation layers, reduce or inhibit corrosion, upgrade crude oil, or address crude oil flow-assurance issues. Injection can be administered continuously, in batches, in injection wells, or at times in production wells.

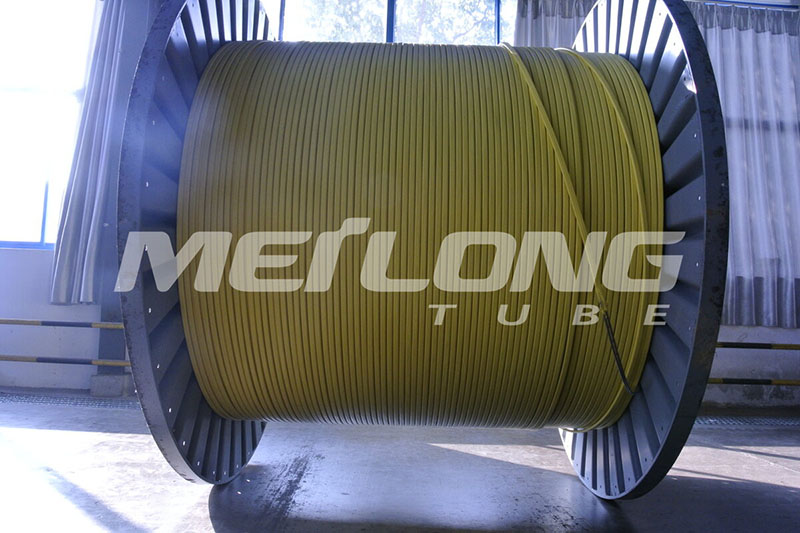

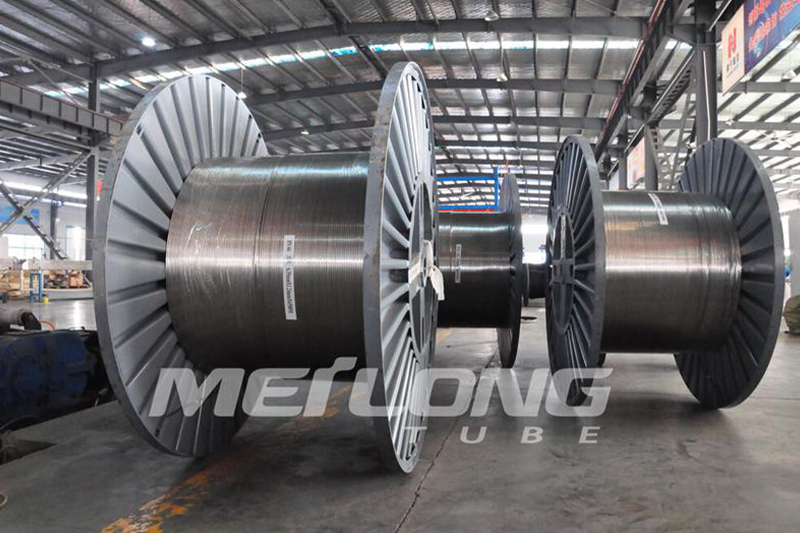

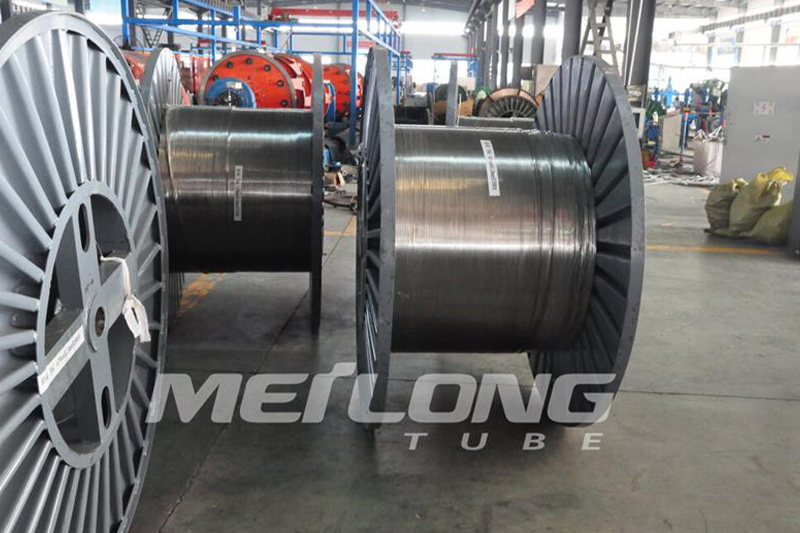

Product Display

Alloy Features

Corrosion Resistance

Organic acids at high concentrations and moderate temperatures.

Inorganic acids, e.g. phosphoric and sulphuric acids, at moderate concentrations and temperatures. The steel can also be used in sulphuric acid of concentrations above 90% at low temperature.

Salt solutions, e.g. sulphates, sulphides and sulphites.

Caustic Environments

Austenitic steels are susceptible to stress corrosion cracking. This may occur at temperatures above about 60°C (140°F) if the steel is subjected to tensile stresses and at the same time comes into contact with certain solutions, particularly those containing chlorides. Such service conditions should therefore be avoided. Conditions when plants are shut down must also be considered, as the condensates which are then formed can develop conditions that lead to both stress corrosion cracking and pitting.

SS316L has a low carbon content and therefore better resistance to intergranular corrosion than steels of type SS316.

Technical Datasheet

|

Alloy |

O.D. |

W.T. |

Yield Strength |

Tensile Strength |

Elongation |

Hardness |

Working Pressure |

Burst Pressure |

Collapse Pressure |

|

inch |

inch |

Mpa |

Mpa |

% |

HV |

psi |

psi |

psi |

|

|

|

|

min. |

min. |

min. |

max. |

min. |

min. |

min. |

|

|

SS316L |

0.375 |

0.035 |

172 |

483 |

35 |

190 |

3,818 |

17,161 |

5,082 |

|

SS316L |

0.375 |

0.049 |

172 |

483 |

35 |

190 |

5,483 |

24,628 |

6,787 |

|

SS316L |

0.375 |

0.065 |

172 |

483 |

35 |

190 |

7,517 |

33,764 |

8,580 |

|

SS316L |

0.375 |

0.083 |

172 |

483 |

35 |

190 |

9,749 |

43,777 |

10,357 |

Product detail pictures:

Related Product Guide:

No matter new shopper or old customer, We believe in very long expression and dependable relationship for factory customized Alloy 825 Chemical Injection Line Tube - Chemical Injection Line – MEILONG , The product will supply to all over the world, such as: Orlando, Azerbaijan, Nigeria, With the spirit of "high quality is our company's life; good reputation is our root", we sincerely hope to cooperate with customers from at home and abroad and hope to build a good relationship with you.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!