100% Original N06625 Chemical Injection Tube - Inconel 625 Chemical Injection Line – MEILONG

100% Original N06625 Chemical Injection Tube - Inconel 625 Chemical Injection Line – MEILONG Detail:

Alloy Materials

| Austenitic: | 316L | ASTM A-269 |

| Duplex: | S31803/S32205 | ASTM A-789 |

| S32750 | ASTM A-789 | |

| Nickel alloy: | N08825 | ASTM B-704; ASTM B-423 |

| N06625 | ASTM B-704; ASTM B-444 | |

| CuNi alloy | Monel 400 | ASTM B-730; ASTM B-165 |

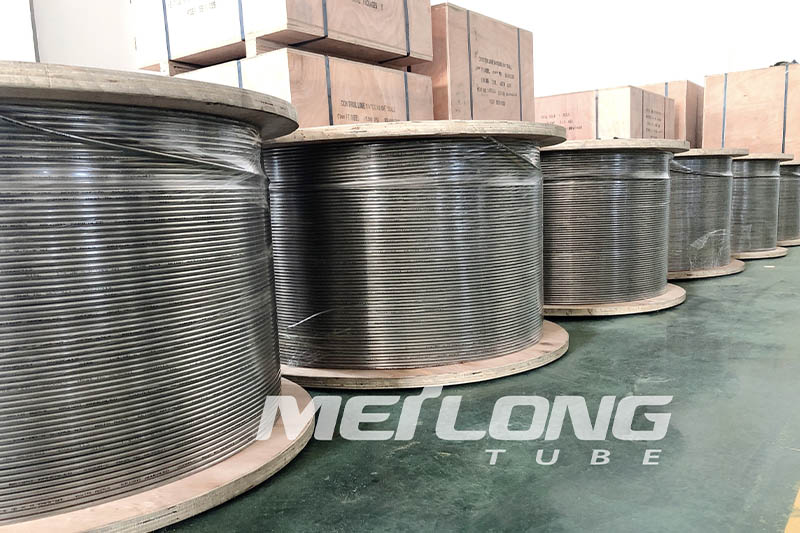

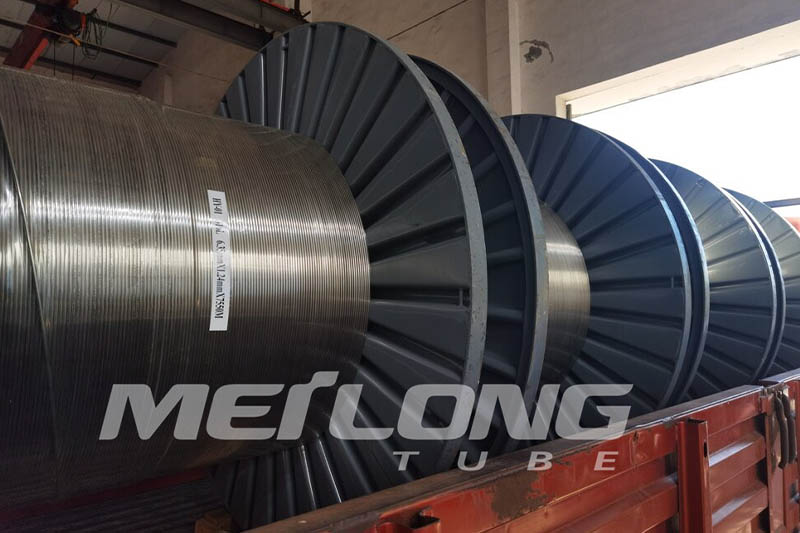

Product Display

Alloy Feature

Inconel 625 is a material with excellent resistance to pitting, crevice and corrosion cracking. Highly resistant in a wide range of organic and mineral acids. Good high temperature strength.

Characteristics

Excellent mechanical properties at both extremely low and extremely high temperatures.

Outstanding resistance to pitting, crevice corrosion and intercrystalline corrosion.

Almost complete freedom from chloride induced stress corrosion cracking.

High resistance to oxidation at elevated temperatures up to 1050C.

Good resistance to acids, such as nitric, phosphoric, sulfuric and hydrochloric, as well as to alkalis makes possible the construction of thin structural parts of high heat transfer.

Application

Components where exposure to sea water and high mechanical stresses are required.

Oil and gas production where hydrogen sulfide and elementary sulfur exist at temperature in excess of 150C.

Components exposed to flue gas or in flue gas desulfurization plants.

Flare stacks on offshore oil platforms.

Hydrocarbon processing from tar-sand and oil-shale recovery projects.

Technical Datasheet

|

Alloy |

O.D. |

W.T. |

Yield Strength |

Tensile Strength |

Elongation |

Hardness |

Working Pressure |

Burst Pressure |

Collapse Pressure |

|

inch |

inch |

Mpa |

Mpa |

% |

HV |

psi |

psi |

psi |

|

|

|

|

min. |

min. |

min. |

max. |

min. |

min. |

min. |

|

|

Inconel 625 |

0.375 |

0.035 |

414 |

827 |

30 |

266 |

8,426 |

26,930 |

11,200 |

|

Inconel 625 |

0.375 |

0.049 |

414 |

827 |

30 |

266 |

12,096 |

38,657 |

14,966 |

|

Inconel 625 |

0.375 |

0.065 |

414 |

827 |

30 |

266 |

16,583 |

53,000 |

18,922 |

|

Inconel 625 |

0.375 |

0.083 |

414 |

827 |

30 |

266 |

21,560 |

68,896 |

22,916 |

Product detail pictures:

Related Product Guide:

Our crew through skilled training. Skilled skilled knowledge, strong sense of company, to meet the company wants of customers for 100% Original N06625 Chemical Injection Tube - Inconel 625 Chemical Injection Line – MEILONG , The product will supply to all over the world, such as: Ecuador, Canada, Kyrgyzstan, Our products are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.